Every company has an operational plan and all departments are required to follow this plan.

However, irregularies often occur in the execution of orders that require management intervention. These interventions (firefighting) demand that time and energy be spent solving the problem, often at the expense of other priorities.

The best plan is worthless if the processes in the company cannot carry it out. At KPC Lean Consulting, we don't just improve your planning quality, we also focus on ways to help departments execute this plan by improving their processes, systems, methods and standards. We attach great importance to a holistic approach, which includes all areas of your company.

As a team, we work together to develop processes and standards that ensure the smooth execution of your production plan.

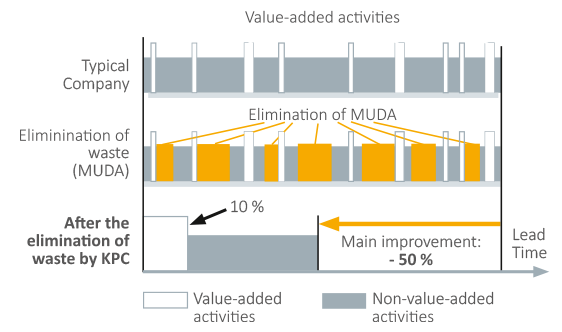

Eliminate waste and reduce lead time using the Lean Management method

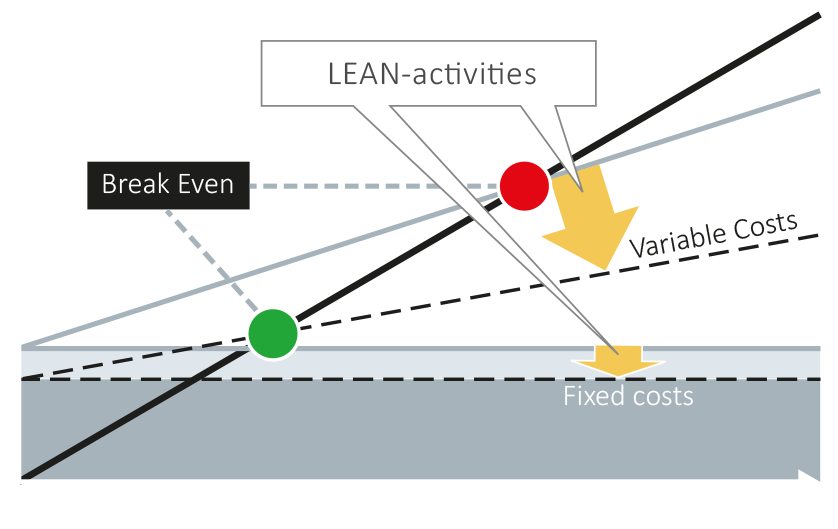

Our goal is to establish a sustainable lean management system for your company. In doing so, we always focus on quantifiable goals and results, so that in the end, manufacturing costs are reduced and there is a visible impact on the operating result.

We pay special attention to the lead time metric, as its actual number always reflects the company's current process capabilities.

Our consulting focuses on increasing the proportion of value-added time. Based on these findings, a process is developed that sustains shorter lead times for the long term.

KPC consulting concentrates on optimizing the value-added chain. We do not just focus on numbers, production costs, quality issues or sick time, but work together with employees to solve daily problems on the shop floor.

If a coach only demands victory from the team without giving guidance on how to achieve it, this leads to resignation. Just concentrating on results is demotivating.

KPC lean consultants develop solutions together with your employees in order to achieve the set lean goals.