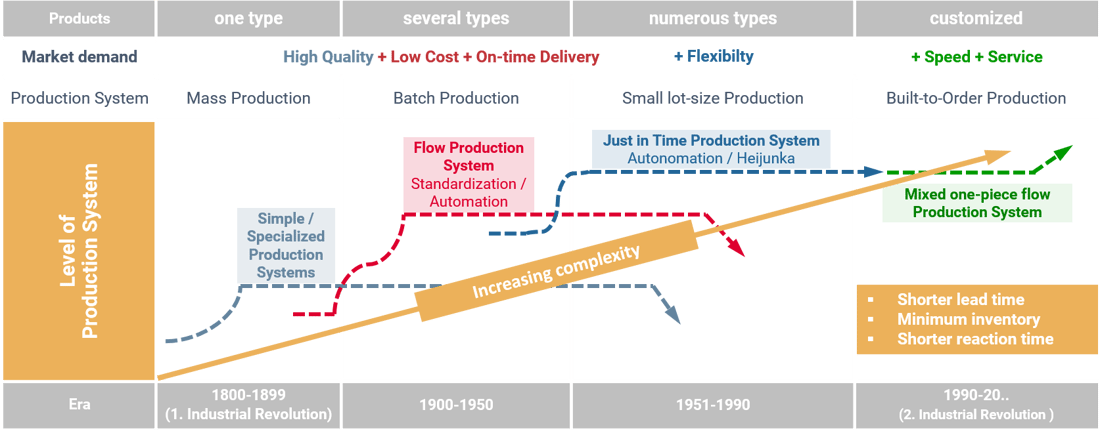

In the past, as now, the industry expects high quality products at fair prices and with ready availability. In global competition, individualized customer requirements lead to greater complexity in order processing. There are also other challenges such as environmental protection and sustainability.

Such diverse challenges can only be managed if we start optimizing all processes so that all resources in the entire value-added system are used more efficiently and in a more targeted manner.

"Lean" means designing all processes, methods and systems, whereby material, resources and energy are used synchrone and just-in-time, creating a perfectly "orchestrated" system - similar to an orchestra where the interaction of instruments is perfectly coordinated by the conductor, resulting in harmonious and enjoyable music.

Despite the use of relevant lean consulting or Kaizen training in lean academies, the problems or challenges cannot usually be solved in a sustainable manner. Knowing the theory is one thing, putting it into practice in-house is another.

In our experience, manufacturing companies are often confronted with the following challenges along the value-added chain: