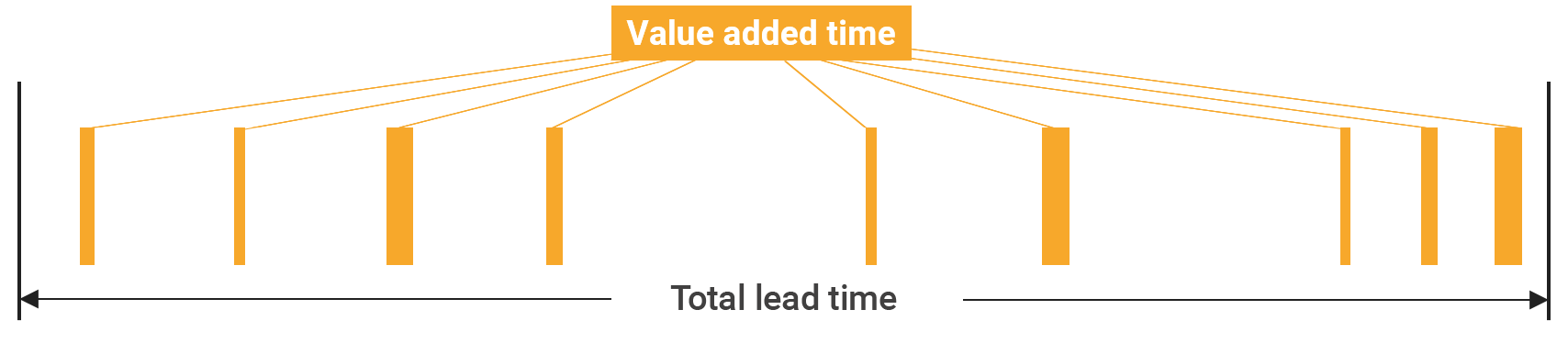

Today, the necessity to produce quality products at acceptable prices is self-evident. The challenge for production companies is how to reduce overall lead time and inventory under the maxims: manufacture more cost-effectively, serve customers faster and react more quickly to market changes.

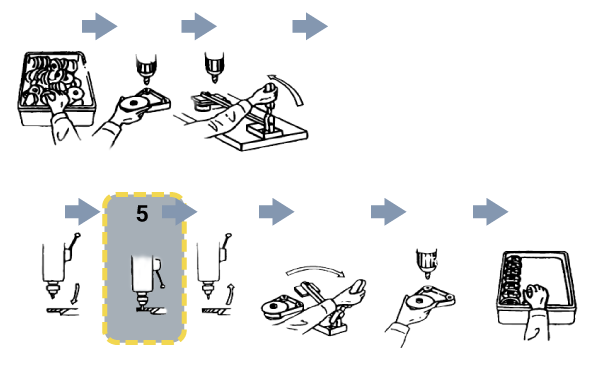

The answer lies in the "ruthless" analysis of all processes and their radical and continuous improvement.

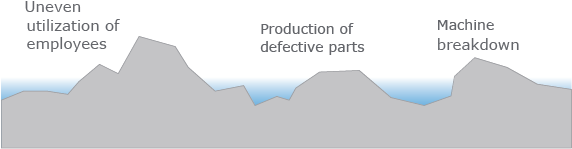

The water line of long lead times and high inventory conceals many of the company's underlying problems.

Lowering inventories and reducing lead times

make these problems visible.

It is not enough just to increase machine productivity or write about the theories of quality assurance.

These are often used to conceal a lack of willingness to employ the concepts of continuous improvement in the process flow.

Our lean consulting services focus on localizing problems in the processes and coaching employees on how to effectively eliminate them.